Munckhof Tunnelsprayer My dream project and dads nightmare

In 2020 i came across a old Munckhof Tunnelsprayer. This is a machine that is being used to spray orchards with crop protection products to prevent infections of tree illness. When spraying an orchard only around 50% of product will hit the tree while the other 50% flies through and eventually ends up on the ground. The speciality of the tunnelsprayer is that it’s built arround the tree and actually blows the product into the tree from two sides cause the product to achieve a zero speed in the middle of the tree and drop down on the leafs. Any product that doesn’t hit a leaf or flies through will end up in the other side of the tunnelsprayer. A suction pump for each side sucks the fluid back from the collectors through a suction filter back into the tank.

The machine itself seems to be from 1993 which for a sprayer is really old, as at the day i bought it, it was 27 years old and that means it’s really rusty and you can expect lots of maintenance. However i always wanted a machine that catches product back again after spraying to do something good for the environment but also to save money. Eventually it is money that we are spraying away.

In 2020 we didn’t have the machine certified yet, so i couldn’t spray properly with it yet. but i did make some test runs to see how it performs, this concluded that the collectors on both sides had to be renewed as they were rusted away completely. also the pump did have some issues, so i took that apart and it seemed a few valvesprings were broken. After replacing these it ran perfect again. The suction pump also has 4 valves, and had 4 broken valvesprings there, so that’s why the suctionsystem worked that bad.

What i really like about this machine is that it’s far ahead of it’s time and that could be noted in the small details. The machine came with the original 27 year old spraycomputer, it has a funny foot with a spring to quickly disconnect it, the steering makes it turn really sharp and it has a complete own hydraulic system so i don’t need to get any hydraulic lines connected to the tractor.

Click here to display content from www.youtube.com.

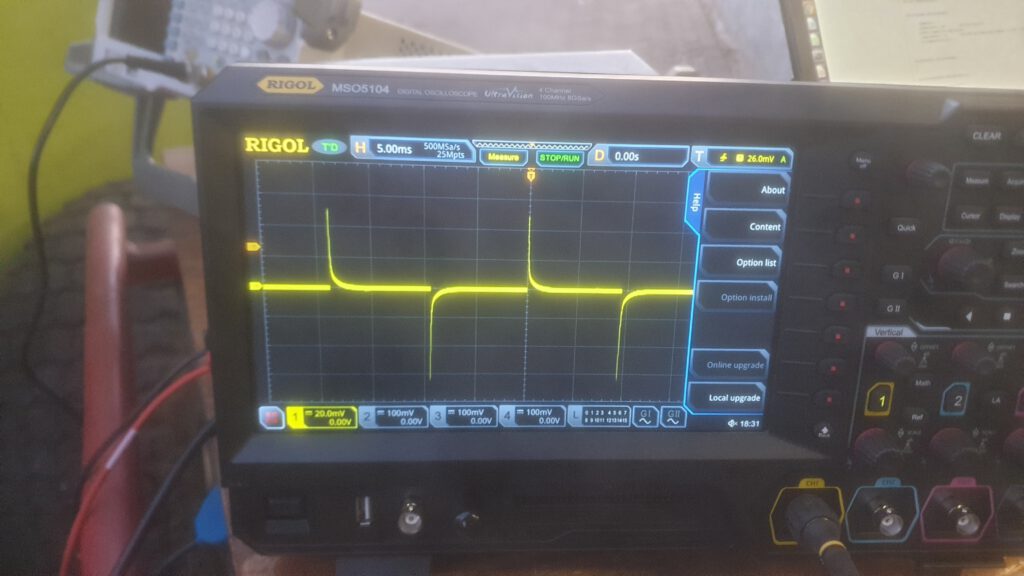

In the winter 2020-2021 i worked hard on the tunnel sprayer to get it in a better condition again. To do so i learnt myself to weld stainless steel with a TIG welding machine. I took the old suction collectors off and made a new construction from stainless steel. This was alot of work. After making that i had to make a sail which collects fluids and leads it into the collectors. All this was completely new for me and a huge learning curve. Eventually i got everything ready to roll and we could start going for the season of 2022. This included a homebuilt spraymonitor based on a webserver running on a ESP32 to have a cheap spraymonitor that shows what i like to see. To manage this i had some struggelings with the flowmeter signals, but eventually got them working correctly after installing a smaller size flowmeter.

Click here to display content from www.youtube.com.

In the beginning driving with this machine costed alot of effort as it’s something else then a normal sprayer. it steers really weird, and requires some space. After getting the hang of it i was able to make every turn in all the fields with 8 km/h. It turns out when you steer correct the machine only requires 5 meters of headland, but it cannot drive over the headland, only turn into the next row as the combination of tractor and sprayer is too wide.

During springtime the sprayer saves about 50% of spraying product. Once the leafs grow onto the trees the saving drops, and by that drop it means we only spray until July with this sprayer as it makes no sense spraying with it after this period and we only risk damaging apples because we can’t see the other side anymore.

Click here to display content from www.youtube.com.

My DIY Spraycomputer

I am a Bachelor mechatronic engineer and i love combining hardware and software in a workable machine, and so i started a project on this tunnelsprayer building my own sprayercomputer. I did that based on a Raspberry as server of the machine, a Controllino for in and outputs and a Industrial Wifi router to connect to the Raspberry.

Everything of this system connected over Ethernet allowing me to excercise with a Controllino and Raspberry Pi to communicate over Ethernet with TCP and JSON files. I created a webserver as interface which loads on a tablet and showed the volume per hectare, and some other variables including tankvolume etc. This always worked very accurate, unfortunaly the webserver sometimes crashes, and the system needed a restart at that time. We drove arround with the system like this for 3 years.

Upgrading to ISOBUS

Being able to spray application maps has always been my goal, and it has been my challenge making that myself, but i got caught up in time here. therefor in end of 2023 we decided to upgrade to ISOBUS to control the sprayer. This would make a universal connection between tractor and sprayer possible, and get rid of a few issues i was having, like for example not being able to close the window of the tractor due to the cable of the tunnel sprayer controlbox.

Upgrading to ISOBUS also ment i could get started spraying application maps with a general GPS setup. So we went for it, and bought everything we required to rebuild the Tunnel sprayer with ISOBUS. We also decided to upgrade 3 tractors with ISOBUS as we like to have a backup for if something goes wrong. You don’t want to have stress to not being able to spray because your tractor with ISOBUS has a plugged diesel filter or something like that.

Upgrading the tractors to ISOBUS

Click here to display content from www.youtube.com.

To upgrade the old Tunnelsprayer to ISOBUS the electric schematic in the manual came of good use as it told me exactly what cable did what.

I then removed the controlbox, the wiring box and a whole lot of wiring harness to eventually make it all new. Now only 1 wire had to go to the front which is really neat as it makes the Tunnel sprayer have only 2 plug able wires (ISOBUS and lights) and a pto shaft and the hitch to attach or detach.

When installing the new electronics i made a nice steel cover to protect everything from damage and also from water damage. Now the flowcontrol, but also hydraulics are being controlled over ISOBUS which allows us to fold and unfold the Tunnelsprayer with the ISOBUS joystick in the cab. This makes operating really comfortable compared to the old switch box.

The setup like this is able to spray application maps with it’s ISOBUS display and so we did give this a few trials and now we do blossom thinning on application maps with the tunnel sprayer and also Growth regulation on application maps to treat only the trees we want to treat.

Upgrading Tunnelsprayer to ISOBUS

Click here to display content from www.youtube.com.

Blossomthinning on applicationmaps

Click here to display content from www.youtube.com.