How i started in the workshop

When i was young i never really got attracted to building,restoring or fixing machines. This came arround at my age of about 19 years old when i was working for a agricultural contractor, and got to drive lots more machinery. Somewhere in 2012 I started making my 3d printer and that got me into making. The 3d printer was my pet and creation and leaded to me getting interested into everything else. In 2014 i was already doing alot of workshop projects, unfortunaly the workshop was a very dirty and bad organised place back then.

It basically was where we stored our tools, my grand uncle parked his car there, and some bicycles. Furthermore it was storage. The only reason to call it workshop was because it has a pit to work on cars.

The mobile workbench

Until 2014 i had always been working either on the workbench, or bringing all the tools over separately to where i am working. This was getting pretty annoying and i had been looking arround for a professional big mobile workbench. Unfortunaly they are soo super expensive, even without their tools that i decided i rather make my own. So we had a frame laying arround from a old Greefa sorter machine. This was completely in the wrong size, so i cut it up, and extended every size until the size that i wanted.

This did work out and made me a nice frame. Then i decided to make all the drawers from wood with Thomas regout linear guidanced which i found on ebay. About 200 euro of wood went into this workbench and 150 euro for the linear guidances. I wanted my drawers to extend 85cm, as the workbench was 80cm wide. This worked out, and got me these massive deep drawer with 0,8m2 space in each drawer. I decided to make full width handles with a heavy metal bar, this way the drawer is really nice to open. After 2 years of usage we bought heavy duty wheels for it which could 500kg per wheel, then make the workbench drive arround really smooth.

The big modular workshop workbench

By 2016 i somehow figured i just couldn’t work in the workshop. The workbench isn’t flat, and basically everything stored there makes no sense, or takes about 100x the space of what the object actually is. I started thinking about how to fix this issue and discuss with my dad what we could do with it. Ofcourse the reaction came “nothing” it’s fine how it is, don’t change it.

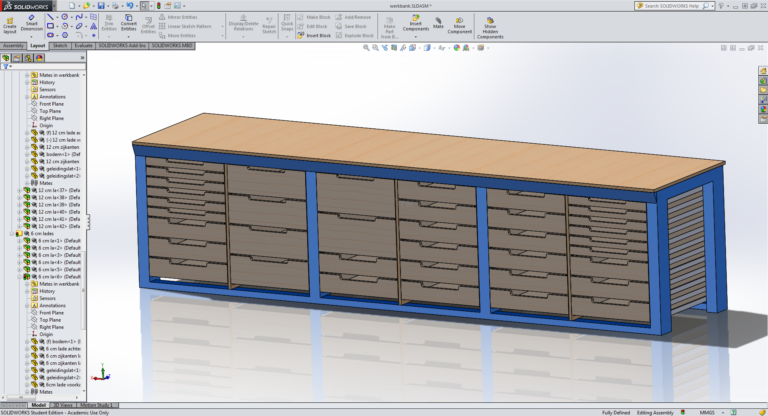

I started doing some drawing work on a idea for a big modular workbench, and had seen the big idea from the youtube channel Jeremy Schmidt (https://www.youtube.com/watch?v=0HPNfQJNBYI&t=271s&ab_channel=JerSchmidt) to build it modular. Making the drawing, and figuring the modular design out cost me about 2 months of drawing in the evening (I had to learn it).

The concept came down to a 3,6 meter wide cabinet which i would build from wood we had laying arround. inside that would come 36 drawers which would all be exactly equal in width and length. The only variation would come from the height as i wanted 4 different heights so i could store different stuff in different drawers without wasting too much space. It’s all about efficient space usage in a small workshop like mine. I figured out that the workbench should sit opposite to my lathe, that way i could store lathe tools in there and reach for them easily.

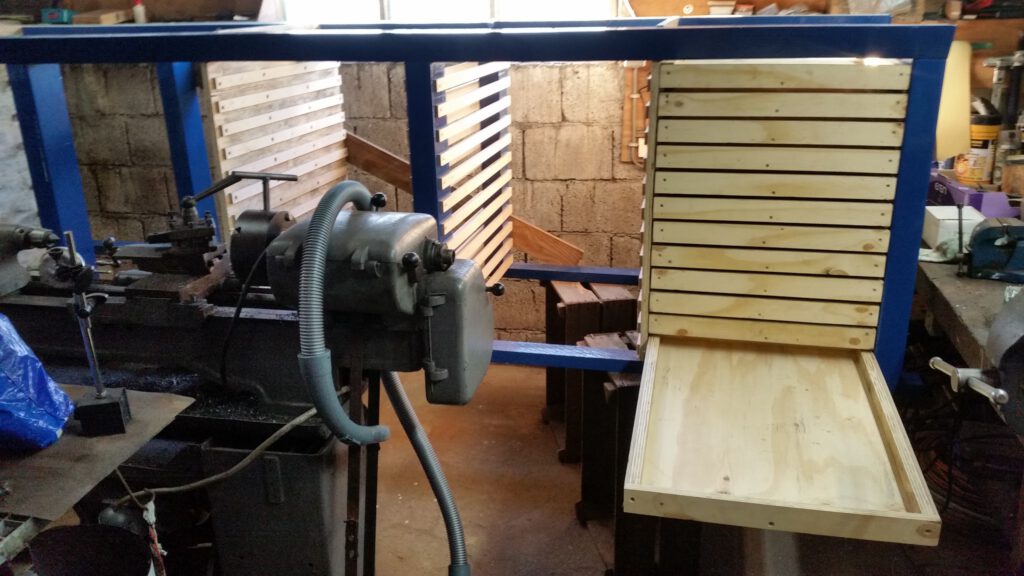

I made the frame out decent wood, and gave it that nice blue color which still shines today. for getting all drawers on the same distance i used a template piece of wood and screwed and glued everything in place on the same distances. The drawers where actually alot of work. Making 36 the same drawers sounds easy, but it costs alot of time to make them all accurately the same. Once done and put in they were stuck solid. Unfortuanly they didn’t slide easy as the fitting was pretty precise. It was only after moving the drawer in and out alot, and putting wax on there that i could get them to move. Once i got them moving smooth it was a joyful sight to see this cabinet sit in it’s place as it’s just gigantic compared to the mess that was in this corner before.

The drawers needed handles. I considered to saw them out, but i liked to have well closing drawers especially with me welding that near to the drawers. I had my sanding belt only for a few months back then and it had a special polish belt, and i decided to give that a go and make polished steel handles. This costed alot of energy to make, but the result is great.

The handles are fixed in place very well so i can pull on them which is defenitly necessary. Some of the drawers by now weigh over 100 kg with the bolts in there. They slide pretty easy because i keep this well lubricated with wax. Everything is built too last and nothing is bending by that load. I can even pull them out to use as a step up when i need to stand on my workbench which is great. jumping doesn’t even give a sound. i decided the color grey would look well with the blue, this makes it immune to dirt and wear or dust as the color just covers that, and even 8 years later they look great.

Click here to display content from YouTube.

The next cabinet in the sortinghall

Ever since i built my workbench in 2016 i wanted to build another one. In our sorting hall we have a lot of stuff laying around unorganized. This has been bothering me for a while and i decided to make another huge drawer cabinet here where we can sort out everything related to fruit growing that should fit in a drawer. I started working out the plan from the original one of my workshop. The drawers had to fit old and new workbench to have 1 modular drawer design.

At this cabinet i decided to make the construction even heavier by adding big wood between each drawer to make it even more stable then version 1. especially getting all the drawer guidances in was very time consuming. For this cabinet i decided it might be easier to let all the wood come pre sawed. that way i only had to assemble the drawers, and not saw them all as that would be the hardest job for me. This cabinet got 33 drawers, but is basically 2 low slots higher then the previous one adding 15% more space in this cabinet as the one in my workshop.

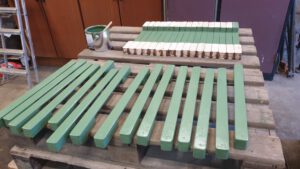

The whole workbench is painted in machine color green, which is a color we use alot and is also the color of all accents of the sorting hall. That makes this color great for this application. For the handles i decided to make them out of wood and full length of the drawer which worked out really nice.

This workbench is a nice looking one, it has floorplanks on top for cleanability, a foldable whiteboard, and i decided to cover up the whole backwall aswell with paneling to make this look way nicer. This turned out really nice eventually and made this corner look alot cleaner. Since this is the entrance for traders, and the meeting point for everybody it’s really neat to have this look good. Inside the drawers we store all kinds of tools, but also advertisements stuff and labeling stuff for example. Basically everything you need when you are in fruit logistics

Click here to display content from YouTube.