Type: Infratirea G25

Buildyear: 1974

Weight: 1100kg

Power: 3KW

Voltage: 400V

Adaptersize: MK4

max RPM: 1800

Drillgears: 12

Autofeeding: 9 Gears

We always had a drillpress in our workshop which dad bought somewhere in the end of the 1980’s. This drillpress has us made alot of things, and got me through most of my childhood. The machine is about 1.6m high and is adjustable until 1m between the bed and the drillpress.

This drillpress is very light with only 750W and has a V-belt drive which often quickly starts to slip when drilling. The bed itself tends to bend a little bit, causing a deep drill to always break your drillbit. I had been searching the internet for a big drillpress for 2 years already by this time when my future machine popped up on ebay. It weighted 1100 kg and was standig 40km from my home. The machine was cheap but hard to transport. I went to pick it up with our tractor and the small trailer. After 2 hours driving i arrived at the location. We looked at it, and the machine was as big as a euro pallet and over 3m high. We got the machine on the trailer with a tractor with heavy forklift. After tightening it well the trailer was nearly 4m high with the massive machine on there.

I had to park this drill until after harvest as we were just starting apple harvest. once we finished harvest i started figuring out how to get this machine fitted inside the workshop. To get it fit i eventually had to remove a cabinet and all the other junk and reorganise how machines were standing in the workshop. This took a few tries, but eventually i got them spaced how i like.

The Drillpress

Click here to display content from www.youtube.com.

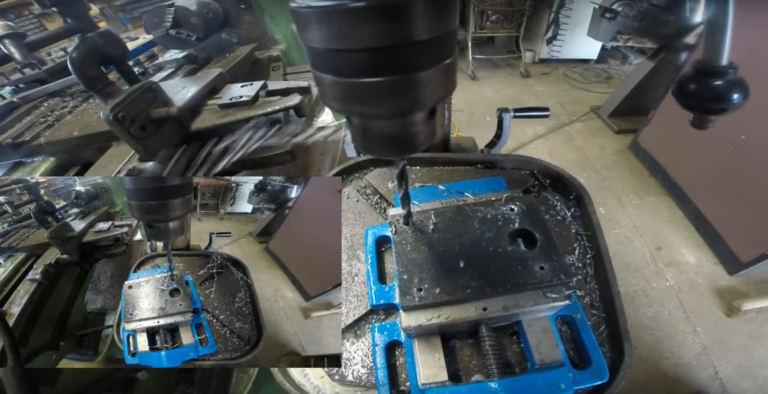

The machine had a 63A 400V connector which was way oversize for me and i had to replace it with a 16A variant. When doing so i installed a reversable plug to make it easy if we ever have to swap phases for some reason. After positioning it i realised that the clamp which i had was quite on the “small” size. it led to me searching for a crosstable and a decent clamp. After about 6 months i got lucky and found one cheap but in a not nice looking shape. I also found a cheap clamp which had some damage on the internet.

I had the clamp being shipped by post, and picked up the crosstable 150km away. Eventually i decided to restore both parts, and give them a proper paintjob.

The crosstable + clamp

Click here to display content from www.youtube.com.

After having everything mounted solid i could drill every hole with this machine. The drillpress in combination with the crosstable and new clamp works fabulous and allows me to drill holes on the exact location i want. Since i got this drill i can make all my parts to exact measurement. This machine really allowed me to make solid perfect parts for the machines i craft.

The drillpress has 12 Gears to go from 50-1800 rpm. A forward and reverse rotation activated by a latch relay with a stop button in the middle.

Autofeeding is possible in 9 different gears with automatic shutoff at the end of stroke, or at the set depth. autofeed get’s enabled again by touching the top again.

Adjustable springtension on the heightlever for either retracting or pushing down with a force.

A nice functioning 24V light.

Tableheight adjustable from 40cm-80cm height.

Drillhead height adjustable from 1.5m-3m.

Original cooling pump which i don’t use.

Retrofitted crosstable with 40cm adjustability.